How To improve asset inventory visibility in real time with UHF RFID technologies - managing inventory across complex networks is challenging when operations are fast-moving and global and how using RFID Readers and RFID Labels Tags improves visibility and control, helping a leading brand enhance accuracy and efficiency in its transport and logistics processes, providing full visibilty and all in real-time!

Improving Real-Time Asset Inventory Visibility with UHF RFID Technologies

Managing inventory across complex, fast-moving, and global networks presents a constant challenge for transport and logistics operations. Traditional barcode systems and manual processes often fall short when it comes to real-time visibility, especially when assets are moving through multiple facilities, vehicles, and geographies.

The Challenge - Enterprises face difficulties tracking the precise location and status of assets such as containers, pallets, returnable transport items, and high-value equipment. Manual scanning can lead to data delays, human errors, and incomplete visibility, which affect operational efficiency, asset utilization, and customer satisfaction.

RFID Technology Advantage - UHF RFID (Ultra-High Frequency Radio Frequency Identification) technology enables automatic, contactless identification and tracking of assets across the supply chain. By integrating RFID readers, antennas, and RFID labels/tags, businesses can achieve real-time, item-level visibility—without the need for manual scanning.

How RFID Technologies Works:

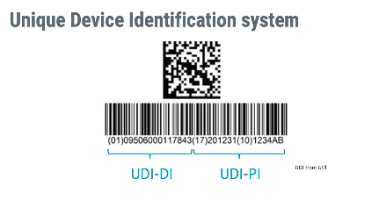

RFID Labels and Tags: Each asset is fitted with a unique RFID tag containing a digital identifier. These durable tags can be read from several meters away, even in challenging environments.

RFID Readers and RFID Antennas: Fixed readers at key points (warehouses, loading bays, gates) and handheld RFID scanners capture tag data automatically as items move through the network.

Real-Time Data Integration: The captured data feeds directly into inventory management or ERP systems, updating asset locations and statuses instantly.

Key Benefits:

Real-Time Visibility: Track assets as they move through facilities and transport routes, reducing loss and misplacement.

Enhanced Accuracy: Automated data capture eliminates manual errors and ensures consistent, up-to-date inventory information.

Operational Efficiency: Faster check-in/check-out processes and improved traceability streamline logistics workflows.

Improved Asset Utilisation: Gain insights into asset usage patterns to optimise resource allocation and reduce downtime.

Scalability and Automation: RFID systems scale easily across sites and integrate with IoT and AI analytics for predictive insights.

Real-World Impact - A leading global transport and logistics brand implemented UHF RFID across its distribution centres and vehicles.

The result:

Inventory accuracy increased by over 98%

Asset search time reduced by 70%

Operational throughput improved by 25%

Data-driven decision-making enhanced via real-time dashboards

Conclusion - By deploying UHF RFID readers and smart RFID labels, businesses gain unprecedented visibility and control over assets across their global operations. The result is a more accurate, efficient, and intelligent logistics network—essential for staying competitive in today’s fast-moving markets.