How to qualifying a potential for a RFID solution, to uncover use-case, environment, performance, and business constraints. Below is a structured, practical checklist one can use in discovery calls or site surveys for a well suited to Auto-ID / RFID project ?

1. Business Objective (Why RFID?)

Start here—this determines everything else.

- What problem are you trying to solve with RFID?

- Inventory accuracy?

- Asset tracking?

- Loss prevention?

- Process automation?

- Compliance / traceability?

- What is not working with your current process (barcode, manual, etc.)?

- What KPIs would define success? (accuracy %, time saved, shrink reduction, ROI)

- Is this a pilot, single site, or multi-site rollout?

- What is the expected timeline?

2. Items Being Tagged (What?)

Critical for tag selection.

- What objects will be tagged?

- Products, pallets, cases, assets, tools, people?

- Dimensions and shape?

- Materials involved?

- Metal?

- Liquids?

- Mixed materials?

- Item value (low-value consumables vs high-value assets)?

- Are items disposable or reusable?

- Quantity:

- How many items in circulation?

- How many reads per day?

3. RFID Tag or Labels Requirements

- Passive UHF RFID expected?

- Read range required? (cm, meters, room-scale?)

- Memory requirements?

- EPC only?

- User memory needed?

- Durability requirements?

- Heat, cold, moisture, chemicals?

- Attachment method:

- Label, hard tag, embedding, adhesive?

- Compliance needs?

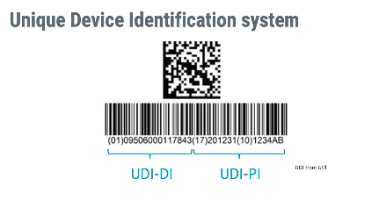

- GS1 / EPCglobal?

- Industry or government standards?

4. Read Points & Workflow (Where & How?)

This defines reader and antenna architecture.

- Where should reads occur?

- Dock doors?

- Portals?

- Conveyor?

- Shelves?

- Handheld scanning?

- Are reads fixed, mobile, or both?

- Directional reading required? (in/out)

- Read speed required?

- Static?

- High-speed conveyor?

- Required read accuracy?

- 95%, 99%, near-100%?

- Do you need bulk reads or individual item confirmation?

5. Environment & Site Conditions

Often the difference between success and failure.

- Indoor or outdoor?

- Presence of:

- Metal racks?

- Liquids?

- EMI / RF noise?

- Ceiling height?

- Reader mounting constraints?

- Temperature range?

- Any health & safety or regulatory constraints?

A Site survey strongly recommended for most fixed RFID projects.

6. Systems Integration

Where RFID delivers real value.

- What backend systems are in use?

- ERP (SAP, Oracle, Dynamics)?

- WMS?

- MES?

- Is real-time data required?

- Do you need:

- Middleware?

- API integration?

- Edge processing?

- Who owns IT integration on their side?

- Data format requirements?

7. Operational Constraints

- Who will operate the system?

- Training requirements?

- Change management concerns?

- What happens when a tag fails or is unreadable?

- Maintenance expectations?

8. Budget & Commercial Considerations

Often left too late—ask early.

- Is budget allocated?

- Are they more cost-sensitive on:

- Tags?

- Infrastructure?

- Software?

- Expected ROI timeframe?

- CapEx vs OpEx preference?

9. Compliance, Security & Privacy

Especially important for people or asset tracking.

- Any data privacy concerns?

- Encryption or authentication required?

- Audit or traceability requirements?

- Data retention policies?