By integrating of UHF RFID Technologies (Ultra-High Frequency / RAIN RFID) with IoT delivers game-changing advantages in the transport and supply chain industries. These technologies shift operations from manual, periodic checks to automated, continuous, data-rich visibility in real time, directly addressing pain points like delays, losses, inefficiencies, theft, compliance, and disruptions.

Here are the major benefits, grounded in real-world deployments and trends as of 2026:

- Real-time end-to-end visibility & traceability UHF RFID enables long-range (3–15+ m), bulk reading of multiple tags without line-of-sight, while IoT connects readers, gateways, GPS, and cloud platforms. This creates live tracking of shipments, containers, pallets, vehicles, and reusable assets (e.g., cages, totes) across warehouses, trucks, ports, yards, and in-transit. Companies gain instant location, status, and condition data — reducing "lost" or delayed shipments dramatically.

- Near-100% inventory & asset accuracy Automated gate/portal reads at docks, yard entries, and loading bays eliminate manual scanning errors. Cycle counts become frequent and fast (often via fixed readers, overhead systems, or autonomous robots), achieving 98–99.99% accuracy. This slashes phantom inventory, overstock, stockouts, and shrinkage — frequently delivering 20–50% labor savings in receiving, put-away, and shipping.

- Faster, more automated logistics processes Hands-free receiving, sorting, loading/unloading, and cross-docking speed throughput. Examples include automated vehicle-mounted or fixed readers detecting tagged packages as trucks pass checkpoints. Major carriers like UPS (equipping tens of thousands of vehicles with RFID readers in 2024–2025) report huge gains in package handling speed, accuracy, and facility productivity.

- Significant cost reductions & ROI Lower labour (fewer manual scans/counts), reduced losses/theft, optimised routing/fuel use, less waste from spoilage or mis-roueting, and better capacity utilisation. Many supply chain deployments see payback in 6–18 months, especially in high-volume logistics, warehousing, and reusable transport item (RTI) tracking.

- Condition monitoring & quality assurance (especially for perishables/cold chain) Battery-free UHF RFID sensor tags (temperature, humidity, shock) feed real-time data via IoT networks. This enables predictive alerts for spoilage, compliance with pharma/food regulations, and proof of cold-chain integrity — critical for fresh produce, vaccines, and high-value goods.

- Improved resilience & disruption management Real-time data + analytics/AI (fed by IoT) allow early detection of delays, re-roueting, predictive maintenance on vehicles/assets, and faster recovery from events (e.g., port congestion, weather). This was a key driver post-pandemic and remains vital amid ongoing geopolitical/trade volatility.

- Enhanced security, theft prevention & anti-counterfeiting Unique serialised identities make diversion, gray-market goods, or counterfeits easier to detect. Tamper-evident tags and IoT-linked authentication add layers of protection for high-value cargo in transit.

- Sustainability & green logistics gains Optimised routes reduce empty miles/fuel consumption; precise inventory cuts overproduction and waste; reusable asset tracking extends lifecycles of pallets, containers, cages. Passive (battery-free) UHF tags align with low-impact IoT goals.

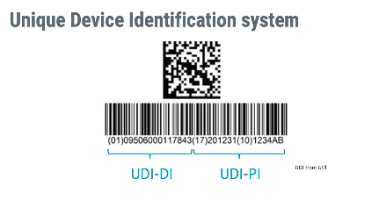

- Regulatory compliance & digital product passport readiness Full traceability supports mandates (e.g., EU requirements, food/pharma safety rules). GS1 EPCIS standards + RAIN RFID enable interoperable, auditable data sharing across partners.

- Scalability for massive networks UHF tags remain cheap (pennies at volume), rugged, and maintenance-free. IoT platforms handle billions of reads/events, integrating with WMS, TMS, ERP, and emerging AI/edge systems.

Real-world momentum in 2025–2026 includes:

- Major logistics players scaling UHF RFID across vehicles and facilities (e.g., UPS's "Smart Package Smart Facility" rollout).

- Reusable transport item tracking in closed-loop systems (e.g., automotive, retail distribution).

- Fresh produce/ perishables traceability (e.g., strawberry supply chains from field to store).

- Airport baggage handling and intermodal container visibility gains.

UHF RFID technologies and IoT turns transport & supply chain operations into intelligent, connected systems and delivering speed, accuracy, cost savings, resilience, and sustainability at a scale that was previously impossible. It's one of the strongest foundations for Industry 4.0 logistics today.