The combination of UHF RFID (Ultra-High Frequency Radio Frequency Identification, often called RAIN RFID) with IoT (Internet of Things) delivers transformative benefits across industries like supply chain, logistics, retail, healthcare, manufacturing, and asset management. UHF RFID provides the physical identification and sensing layer at low cost, while IoT enables connectivity, cloud integration, real-time data flow, analytics, and automation.

Here are the major benefits of using UHF RFID technologies together with IoT:

- Long-range, bulk, contactless reading — UHF RFID reads multiple tags (often 100+ per second) from 3–10+ meters away without line-of-sight, far superior to barcodes or LF/HF RFID. This enables automated gate/portal reading in warehouses, yards, or retail floors.

- Real-time visibility and tracking — IoT connectivity turns passive UHF tags into always-accessible data points. You get instant, global location/status updates for assets, inventory, shipments, or products — reducing "where is it?" issues dramatically.

- Near-perfect inventory accuracy (often 98–99.99%) — Eliminates manual counts, drastically cuts shrinkage, out-of-stocks, and overstock. Retailers and warehouses frequently report 20–40% efficiency gains.

- Massive cost reductions — Lower labour costs (no manual scanning), reduced losses/theft/waste, less over-purchasing, and predictive restocking. ROI is frequently achieved in 6–18 months in large-scale deployments.

- Automation and process speed — Enables hands-free workflows (e.g., receiving, picking, shipping, returns). Combined with IoT, it supports autonomous systems like smart conveyor belts, robotic picking, or self-checkout.

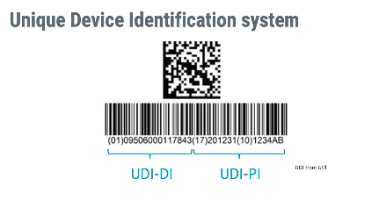

- End-to-end traceability & compliance — Critical for food/pharma (cold chain), luxury goods (anti-counterfeiting), and sustainability regulations (e.g., EU Digital Product Passport requirements rolling out around 2026). Every item gets a unique digital identity linked to history and condition.

- Sensor integration & condition monitoring — Modern UHF RFID tags increasingly embed sensors (temperature, humidity, shock, tilt) without batteries. IoT platforms analyze this data for predictive maintenance, spoilage alerts, or quality control.

- Scalability & low per-item cost — UHF tags are inexpensive (often pennies in volume), passive (no battery = maintenance-free), and rugged. IoT makes scaling to millions/billions of items feasible via cloud platforms.

- Data-driven intelligence & AI readiness — IoT feeds huge volumes of real-time RFID data into analytics, machine learning, and AI. This enables demand forecasting, anomaly detection, optimized routing, personalised retail experiences, and digital twins.

- Improved safety, security & sustainability — In healthcare: better patient safety via equipment/drug tracking. In industry: reduced human exposure to hazards. Environmentally: less waste through precise tracking, plus battery-free tags align with green IoT trends.

In 2025–2026, these advantages are accelerating due to:

- Standards maturation (EPC Gen2v3, RAIN Alliance growth)

- Ambient/battery-free sensing

- Massive tag shipments (billions annually)

- Regulatory pushes (traceability mandates)

- Convergence with AI, edge computing, and 5G/6G

RFID Technologies with IoT moves businesses from periodic, manual tracking → continuous, automated, intelligent awareness of every relevant "thing", often described as one of the most practical foundations of Industry 4.0 and ambient intelligence.