In the manufacturing context, UHF RFID technology enables companies to track and collect data throughout the entire work-in-progress (WIP) process.

Here's how it typically works:

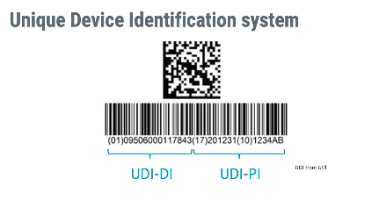

Tags & Label Tagging: Each item or product in the manufacturing process is equipped with an RFID tag. These tags contain a unique identifier that can be read wirelessly by UHF RFID readers.

UHF RFID tags and label - both hard and soft UHF RFID Label Tags can be attached to items or packaging, allowing for real-time tracking of inventory. This enables businesses to automate stocktaking, reduce manual errors, streamline replenishment processes, and improve overall inventory accuracy. Real-time tracking of inventory doing automate stocktaking using UHF RFID Readers - both Fixed-mounted UHF RFID Readers as well as Portable Mobile UHF RFID Readers

RFID Readers - UHF RFID Readers - both Fixed-mounted UHF RFID Readers as well as Portable Mobile UHF RFID Readers placed at strategic locations, such as storage areas, delivery zones, and return counters, automatically capture the presence and movement of tagged assets. This ensures that the rental company has up-to-date information on the location and availability of each asset in their inventory.

Tracking Asset & Products: As the WIP moves through various stages of the manufacturing process, RFID readers placed strategically along the production line capture the tag information. This allows companies to track the real-time location and movement of each item.

Data Collection and AutoID: RFID technology facilitates automated data collection. As the RFID tag labels are read by the UHF RFID readers, data such as timestamps, process steps, and other relevant information are captured and recorded in a centralized database. This eliminates the need for manual data entry and reduces errors.

Process Automation: By integrating RFID technology with manufacturing automation systems, companies can automate various tasks and processes. For example, RFID tags can trigger specific actions or workflows based on predefined rules or conditions. This can include automated inventory management, quality control checks, routing decisions, and more.

Benefits of using UHF RFID technology in manufacturing include improved operational efficiency, enhanced inventory management, reduced errors and manual intervention, increased traceability and visibility, and better overall process control. It enables companies to have real-time insights into their production processes, identify bottlenecks, optimize workflows, and make data-driven decisions to improve productivity and customer satisfaction.

RFID UHF technology plays a crucial role in streamlining and optimizing manufacturing processes by providing accurate, real-time tracking and data collection capabilities throughout the work-in-progress journey.